No.159,Taixin road,Ningxi town,Zengcheng districtGuangzhou, China

+86-13822298758/13922700490Free time

Monday - Saturday Sunday CLOSEDit's all about integrity!

No.159,Taixin road,Ningxi town,Zengcheng districtGuangzhou, China

COMPANY NEWS

THE QUALITY EVALUATION PROCESS OF POLYCARBONATE EMBOSSED SHEETS

- Jul 06, 2019

- Posted by: Admin

- Category: NEWS

You need to evaluate the quality of the product you would wish to buy due to the increasing number of counterfeit products.

Quality evaluation is one of the most challenging processes since some test require sophisticated equipment. Some of the most common examples may include determining yellowness index (YI), analyzing light diffusion, analyzing tear strength etc.

Here are some steps that can help to evaluate the polycarbonate embossed sheets. They include:

1.Choice of Manufacturing Company

Have you identified a company? You need to buy these products from a reputable, licensed, reliable and experienced manufacturer. Most companies which have been in this industry for decades and have a good record of producing quality polycarbonate sheet will most definitely produce quality products.

2. Product Warranty

If the manufacturer doesn’t trust its own embossed polycarbonate sheets by failing to give a warranty, then; why should you have confidence in that product? Avoid a product which does not have a warranty. Depending on the grade of UV protection or anti-abrasion coating, these companies may offer a warranty period which may last for five, six or ten years. A polycarbonate product with a warranty period of about 10 years will imply that the product has been tested and certified that it can remain effective over time frame indicated.

3. View product samples

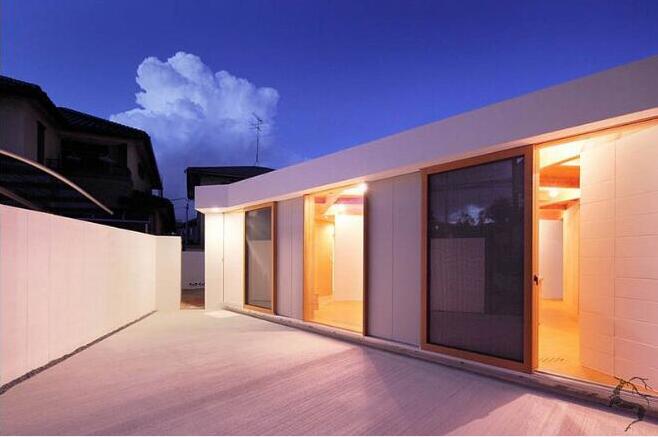

You can request for sample projects where these products have been used in the past. You can get such information from the company’s website. A company whose products have been used to construct reputable structures such as stadia will be a clear indication of quality polycarbonate embossed sheets.

4. Labels

Does the polycarbonate sheet have a symbol indicating that the products are of good quality? This will be a clear indication that after a product has been manufactured; they should pass through quality assurance test.

These are basic procedures which do not require very sophisticated equipment. In fact, within one day, you can be able to ascertain that the product is of high quality. People who fail to go about this process have ended up buying low quality polycarbonate sheets.