Directory

1.Message from the President ——————————————————————————————1

2. Inform Letter ——————————————————————————————————————3

3.Transport and Storage ————————————————————————————————–4

4. Installation Guide ———————————————————————————————————-6

(A) YUEMEI pc hollow sheet installation and application ————————————————-6

(B) Performance of YUEMEI pc sheet ——————————————————————————-10

(C) YUEMEI pc hollow & solid sheet installation requirement —————————————–10

(D) To install curved PC sheet: —————————————————————————————–15

5. YUEMEI PC sheet cleaning and maintenance —————————————————————16

6. Announcements ————————————————————————————————————17

7. Processing ——————————————————————————————————————–18

Message from the President:

Time change.

Our hearts of thanks-giving don’t change,

Customers change.

Our service of quality don’t change,

Season change.

Our loyal promises don’t change,

Building more comfortable environment with our thanks—giving

hearts

Contribute more super service

No matter new or old friends,

We are confident to say:

100% effort,100% competitive products,100% customers‘

satisfaction

From this moment, we must dedicate ourselves to ……

1

Inform Letter

Dear Customer:

Thanks for your trust in our company. To establish stable business with your company, ensure 100% safe when loading & unloading pc sheet, please read below notice:

1. When transport & stock pc solid rolls please follow the mark on the surface. Handle with care, stock it vertically and dry. Don’t come into contact with chromium oxide (like paint, gasoline, thinner, banana oil, paint on the wall), because they will damage the sheet. Don’t strike it strongly.

To put vertical rolls on the ground smoothly, please push the rolls onto a tyre for safe transporting.

2. Notice when transporting pc sheets (solid sheet, embossed sheet, abrasive sheet, prism sheet without packing protective.)

(1) Please wear protective gloves, put up the four sides of sheet to stack in the warehouse. (1.5—2mm, 4-5 pcs in one lot; 3-6mm, 2 pcs in one lot; 8mm or above, 1 pcs in one lot)

(2) Stacking notice: when stacking to 7OCM height. Please cover the corners of the stacking sheets with packing bags or slippy papers to avoid the nether sheets scratch the upper sheets.

(3)Please pull the sheets along with protective tape side.

3.Notice when transporting pc hollow sheets

(1)stacking: one person wear protective gloves and hold the tapes side, shake the sheet to separate the nether sheets, others heave up the mid bottom of the sheets and carry away the sheets. Don’t handle the four corners of the sheets. Don’t touch the two sides of sheets without tapes avoid scratching hands.

When Stacking, please pull along with the length side, not width side to avoid rolling up the film. when stacking to 7OCM height. Please cover the corners of the stacking sheets with packing bags or slippy papers to avoid the nether sheets scratch the upper sheets.

(2)When edge-on stock, must handle the two sides at the same time, then insert it the right place. Must be uniformity to avoid any damage to the four sides of the sheets.

4. Since too many cases of damage to the sheets, protective film due to careless transporting, lead to loss to both of us. We hope that you can read this notice very carefully.

3

1 . Transport and Storage

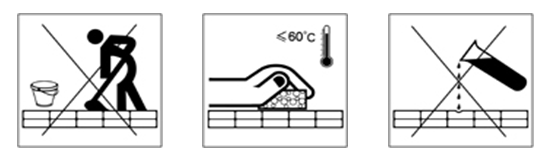

When Carry and Transport the PC sheet, Must be careful, in case of scratch or damage the edge of sheet. Therefore, in order to reduce damage, all the sheets should be packaged, transported, stored according to the following methods.

1. Don’t scratch the surface, damage the edge of sheet, strictly prohibit crashing, can’t be delivered with chemistry goods.

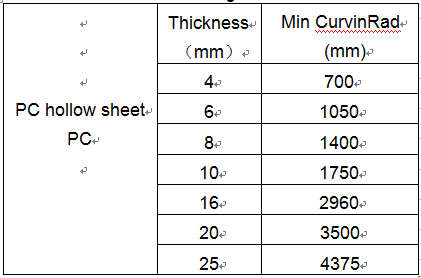

2.The min curving radius should be 175 times for the thickness of PC Hollow sheet. A few sheet can be rolled when delivery, but advise to deliver sheet in pieces. (The bottom of car should be smooth).

3.The min curving radius should be 100 times for the thickness of PC Solid sheet with less 3mm thickness. And it should be 175 Times for the above 3mm PC Solid sheet.

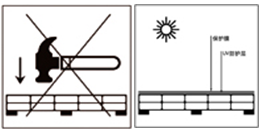

4.Both sides of sheet surface are covered with PE film. The UV protected side should face outwards. To avoid scratching sheet surface do not remove PE film until installation finished.

5.It will be difficult to remove PE film if store PC sheet in place where temperature exceeds 60°C

6.PC sheet should be stored and protected against atmospheric influences like sun,rain, etc. Be careful when handling sheet and keep carriage clean and clear. Pack four corners of PC sheet with paper or cloth to avoid scratches and damages to sheet edges and PE films. PC sheet should be placed during transportation to avoid scratches of sheet surface.

7.Sealing tape on the sheet edge is just used to protect itduring transportation and storage, neither used to prevent leaking nor to install. It should be changed into appropriative tape before installation. Such tape should be of good weather resistance and can maintain its adherence and mechanical strength during long time,maintain its weather resistance and durability during installation and move.

8.Don’t put the heavy goods onto the sheets, nor let the sharp things touch the sheet;

The rolled sheet should be unloaded by machine. or should carefully unload sheets with car diving board. Additionally, PC sheet should not be exposed outside to storage, should be stored shady, cool and full—air place.

9.The cumulated sheet can’t contact with the cement directly. The sheets can’t touch the abrasive things and highly alkaline cleaner. Such as soda, soda salt, amine,aldehyde, ester, ether, carbinol and so on. The paint of the steel should not get in touch with the sheet directly.

4

When delivering and storing PC hollow sheet, must properly use

gasket to package and lie smoothly (The rolled solid sheet should

be straight).

The sheets should be stored under the cool, clean, dry and non-dust

warehouse. Avoid direct sun and rain.

The Stacked Goods’ height is not more than two meters, to avoid

The Stacked Goods’ height is not more than two meters, to avoid

scratches or place heavy objects on the top. The surface with UV

Coating should face the Sunlight direction (It has been indicated on

the PE film)

Before installation, remove 5cm PE film from four edges of

Before installation, remove 5cm PE film from four edges of

the sheet for easy processing.

Don’t walk on PC sheet, when installing need put horizontal

Don’t walk on PC sheet, when installing need put horizontal

wooden plate or other equipments for supporting.

Don’t scratch sheet with sharp tools or knock in a nail directly.

Don’t scratch sheet with sharp tools or knock in a nail directly.

Cut must be smooth, avoid damage.

To set aside enough stretching space according to the thermal expansion,

To set aside enough stretching space according to the thermal expansion,

PC hollow sheet Linear expansion rate: 7.0xl0m/m.k.

5

2. Installation Guide

(A) YUEMEI pc hollow sheet installation and application

Use PC hollow sheet in industrial, residential, and agricultural buildings, designers choose the materials and design should be based on the building’s function, location, climate, environment and users‘ requests on lighting, shading, thermal insulation, fire-retardant, anti-static. After confirming total area of the job, the building shape and the basic structure, the first thing is structure and tectonic contact design, according to the sheet thickness, width and length, decide the cross-section and spacing of the support structure, judge these parameters if reasonable based on safe, durable and beautiful.

Design and install YUEMEI pc hollow sheet

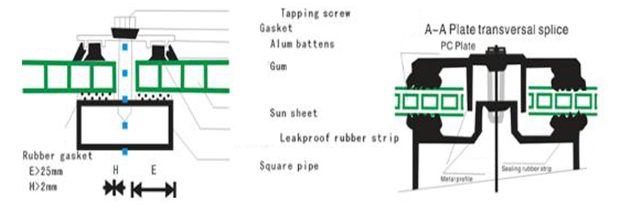

Install PC hollow sheet: According to the sheet features, use professional and technical methods to install the sheet on the frame. And meet the building function and quality of the buildings. use aluminum bar fix the sheet on frame.

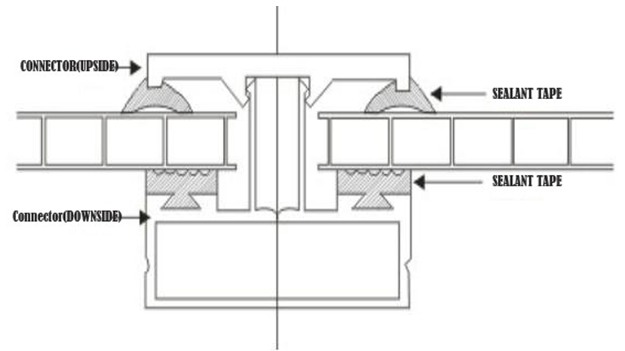

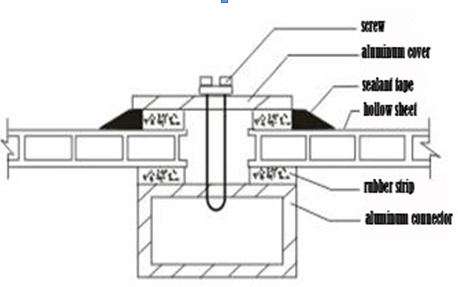

1.Dry—type installation method:

The dry-type, do not use sealant. We recommend accessories with the perfect combination with YUEMEI pc sheet, sheet expansion over the sealant may sometimes occur, and also from aesthetic aspects. From aesthetics, this ‘dry-type‘ installation method is the ideal solution.

The advantages of dry—type installation method: Rubber pad / sealing tape lock sheet, The sealing tape is pressed on the inside of the bar (aluminum profiles). Sheet can move freely in the thermal expansion and shrink.

Warning: Do not use the PVC gasket or sealing tape, Additives from soft PVC transfer to

the sheet surface causing chemical corrosion, lead sheet surface crack, or even the whole board was broken. Suitable seal materials are neoprene or EPDM, a lot of accessories designed specifically for YUEMEI-sheet, easy-to-use, please ask YUEMEI company.

6

2.Wet installation method:

This installation method is Mainly used for small families, the parking garage, the station canopy, rain canopies, warehouses, greenhouses and

many other occasions can be replaced with glass.

Under Wet installation method, The first requirement is that the sealing system must be able to withstand a certain amount of movement, and thermal expansion, and does not reduce the adhesive force with the frame and sheets.

YUEMEI pc sheet, we recommend to use neutral silicone sealant with PC hollow

sheet in wet assembly, but must pay more attention to check sealant’s chemical

character before using it, absolutely it is not allowed to choose amines, benzoic acidamine-containing acidic, alkaline silicone gel because these curing agents will corrode the sheet, and then cause the sheet to crack. Especially when there is internal stress, besides checking sealant’s chemical character. We should be consider the chemical compatibility, elongation and weatherability etc.

3.Edge seal

Any time, installing YUEMEI sheet, rib must be downwards to discharge the

condensed water, or other condensations will be deposited in the channel, under particular temperature to form a green impurity, in order to avoid the moisture accumulation and dust/insect

7

contamination in the channel, Therefore pay attention , especially in the opening end of the channel.

Note: the tape on YUEMEI Hollow sheet, only for protecting the edges of the sheets during the transportation and storage, which is not used for waterproof or installation, and it is not anti aging. When being installed, this tape should be replaced with a special edge sealing tape. After cutting, we must use special edge sealing tape to seal the two edges of the sheet. Project tape should have good weather resistance, long—term use without losing their adhesion and mechanical strength, when operating tapes we need to pay attention to the following points can significantly reduce pollution:

(1). Ensure that all the edges smooth before sealing.

(2). Before sealing, we must blow dust in the channel, compressed air must be free of any impurities. Dried

(3).To ensure that the profiles, metal cover, U-shaped end protection slot cover the tape completely. Portion should not be exposed after installation.

(4).In the pre—installed before last rack mount, we need to check if there is loss of the tape, and a damaged tape must be replaced

(5).About anti-dust tape, please ask for YUEMEI salesman.

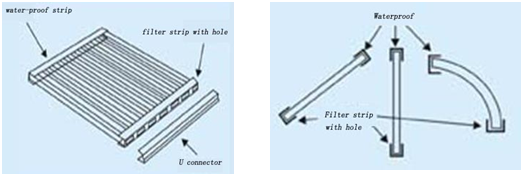

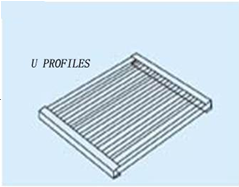

4. Flat sheet sealing method:

Standard method: Top notch with waterproof tape sealing, the bottom of the notch use tapes with hole on it. See picture.

YUEMEI PC U profiles are good for covering the tapes with hole on it, its advantages:

(1).Minimize dust entering

(2).To facilitate condensate discharge

(3).Slot ventilation to prevent the formation of excessive condensation

(4).Ease of cleaning

8

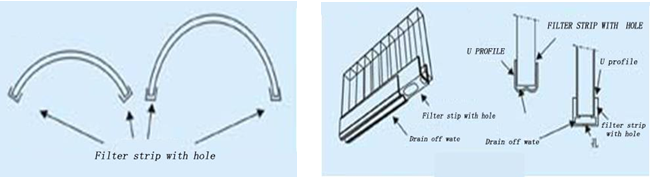

5. Curved sheet sealing method

When install arc-shaped vault, slots at both ends must seal with tape including holes on it. See picture.

Note: both ends of sheet must be kept clean, to facilitate the discharge of condensation.

Special environmental edge sealing method:

In a particular environment, it is recommended that Slots of

both ends of the sheet with a waterproof tape sealed.Figure:

(1) Extremely polluted environment

(2) Low temperature / dry environment

(3)Small temperature difference between inside and

outside

6. Flat sheet installation

(1).Sustain Factor .

No matter what sustained structure you used, PC sheet’s ribs always must be acclivitous and down, PC sheet’s width vertical with ribs, length is horizonta with ribs

(2).Acclivitous installation

Acclivitous installation, Is for easy and convenient to flow out water, so the easy Acclivitous Angle is less than 5°

9

(3).Top Installation

(3).Top Installation

In procedure of top installation, when installing or cleaning, people should not stand on the sheet, it must have wood panel or others on the frame works.

7. Insertinstallation

Cut off 5—10mm of the protective film before inserting PC sheets to the support frame, because the protective films would cause inefficient adhesive between tamping and PC sheets.

Since the expansion and contraction degree of PC sheets, is different from that of metal frames, as well as PC sheets are flexible and taking air pressure, therefore, appropriate insertion, reserving space for expansion and shrink because of temperature changes, and choosing suitable thickness of PC sheets are necessary.

General plate should be inserted into fixed frame for over 25mm,with at least 2 ribs installed into the fixed zone,3mm space need to be reserved for expansion or shrinkage.(expansion ratio:0.065mm/m°C)

( B) Performance of YUEMEI pc sheet

1. The mechanical properties

(1). Impact strength: PC sheet have excellent impact performance, it is 80 times higher than traditional glass, 30 times higher than acrylic sheet. The impact strength the PC solid sheet wins a beautiful name “transparent steel sheet”.

(2). Tensile strength is good, PC solid sheet have good heat resistance

10

(3). Bending strength: PC solid sheet have good flexural resistance, even if the bending angle of 90 ° , still no rupture.

(4). Anti-fatigue and creep resistance: creep resistance of PC solid sheets is the best in thermoplastics. The creep is very small even at high temperatures.

2. Thermal properties

(1). Maximum Operating Temperature: PC solid sheets‘ melting shapedtemperature is 135 °C,continuous use temperature is 120°C.

(2). Linear expansion coefficient: The linear expansion coefficient is 7 x 10-5cm/cm°C Which is the smallest in plastics.

(3). The embrittlement temperature: PC solid sheets‘ embrittlement temperature is -40 °C, the lowest continuous use temperature is —30°C,other general plastics are not comparable.

(4). Combustibility: PC solid sheet is one of the plastics with flame retardant and self—extinguishing, no toxic gases when heated.

(5). Thermal conductivity: PC solid sheet’s thermal conductivity is little different The general plastics, it’s 1/4 of glass, 1/300 of iron, 1/1000 of aluminum, 1/2000 of copper, pc solid sheet is one of the materials with excellent heat insulation properties.

3. Optical properties

(1). Light transmittance: PC solid sheet’s light transmittance is more than 85%, like glass.

(2). Weather fastness: Generally, PC sheet is long-term exposure outdoors, easy to be caused yellowing and surface degradation by ultraviolet radiation. The sheet surface must be coated by anti-UV layer, even if long-term exposure outdoors,no significant change in its optical or mechanical performance.

4. Sound insulation

YUEMEI PC solid sheet’s sound insulation is 3-4DB which is better than glass, so PC solid sheet is the best choice for highway noise barrier material.

5. Chemical resistance

Polycarbonate have good properties resistance against weak acid , weak base and the alcohol at room temperature, but less resistance performance against strong acid,benzene, chlorinated hydrocarbons and esters .They are easy to be dissolveel,swelling or decomposition. As its chemical resistance is related with temperature,internal residual stresses and the duration of exposure, please pay special attention before using. (check PC solid sheet incompatible chemicals Instruction)

11

6. lightweight

Under the same thickness and area, the weight of PC solid sheet is only half of glass,so it can save you a lot of freight cost and easier for construction.

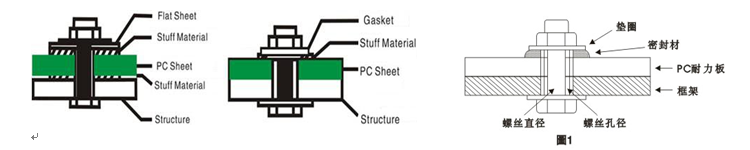

(C) YUEMEI pc hollow & solid sheet installation requirement

1. Pre-Installation Considerations

(1). Clean the metal frame work, no metal elbow oil or other chemicals remaining on the frame, paint side of the frame cannot contact sheet.

(2). Reserve the expansion space, the expansion space can be calculated as the

following formula:

Expansion = linear expansion coefficient x length x maximum temperature

variation

The linear expansion coefficient: 7 x 10-5(cm / cm / °C)

Example: 100cm length PC sheet is installed in the 40°C diurnal temperature

environment, the reserved space for expansion:

Swelling value = 7 x 10-5 (cm/cm / °C) x 100 (cm) x 40 °C = 0.28 (cm)

The reserve space for expansion is O.28cm at least.

(3). Additives precipitated from PVC gaskets and chemicals from some rubber

gaskets will be moved to the gasket surface, if touching PC sheet, they will

destroy PC board, therefore, forbid using. Recommend material for gaskets

:EPDM RUBBER (EPDM), Silicone Rubber (silicone rubber) and Neoprene rubber

(neoprene). If no suitable gaskets, you would rather not use, but not choose

gasket which will destroy the PC sheet.

(4). Sealed installation needed, you can choose neutral sealant, as well as double-sided waterproof tape and rubber bar.

12

(5). Beside waterproof, double-sides waterproof tape also can be used for cushioning material between the PC sheet and frame. Some double-sides tape

glue face may destroy PC sheet, careful selection during construction.

(6). When cutting pc sheet, must use the power tools, it’s better to choose

tungsten carbide material, before cutting must fix sheet to avoid vibration.

(7). PC sheet can be scratched easily, don’t remove the protective film when

cutting. Must mark line on the protective film before cutting, if mark on the sheet directly, please use crayons, don’t use sharp tools.

(8). In new buildings before the cement is completely dry, don’t contact with PC sheet directly, or alkaline substances in the cement will destroy the PC sheet material.

(9). If PC sheet need to be bent, its construction radius must be bigger than to allow the radius of curvature.

(10) .If dust on PC sheet surface, first wipe dirt with a soft cloth or sponge with neutral detergent, then rinse thoroughly with water, and finally dry with a soft cloth.

(11). If use solvent cleaning pc sheet, remember that most of the solvent, such as toluene, acetone, gasoline, carbon tetrachloride, the PC sheet will be

destroyed, so must not use. Recommend solvent of alcohols, such as

anhydrous ethanol or isopropanol, etc..

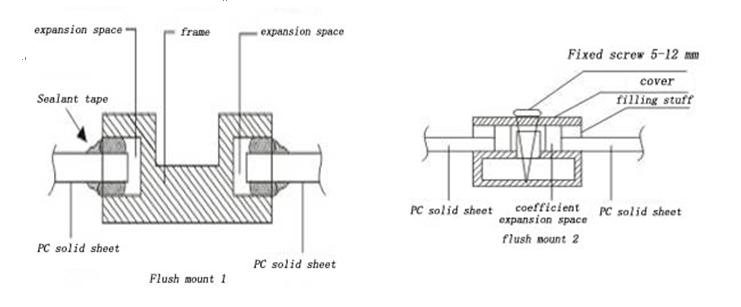

2. Common installation method

(1 ). Embedded installation method

1). The film on the PC sheet will interfere with the adhesion of the seal profile, so before embedding pc sheet, remove protective film 5-1 0cm.

2). When embedding PC sheet, need appropriate the embedded amount and expansion space. If embedding too small, the PC sheet may fall off due to wind pressure or other heavy pressure; If without enough expansion space, the PC sheet is due to the expansion of the stress, causing damage.

13

1). The size of the screw holes need to be different during summer or winter, day or night, the PC sheet thermal expansion and contraction is different. And the drilling installation allows sheet expansion of shift, to prevent thermal expansion and contraction, in general, the drilling sheet of open hole diameter shall be 50% larger than the diameter of the bolt or rivet.

2). The position of the screw holes is too close to the edge of the pc sheet will be very easy to cause rupture. In general, the position of the screw holes should not less than 50mm distance from the edge of the PC sheet, the screws cannot be too tight, otherwise deformed burst and cause stress.

3). The distance between screws, according to the sheet thickness for proper

configuration, the distance is too short or too long is not good. If distance is too short, too tight may caused stress, causing damage; if distance is too long, it may make the PC sheet unstable. The recommended screws should not too

dense, 50cm or more per screw (the thicker sheet the longer distance between

screws required).

4).Your can plant the gasket so that to reduce pressure from the screw directly, but the PVC gasket, rubber gasket or waterproof rubberized fabric of containing asphaltum component may break the PC sheet, they can’t be used. The EPDM rubber, silicone rubber and Neoprene rubber are recommended.

5). When cold processing, don’t use screws inside the bent portion.

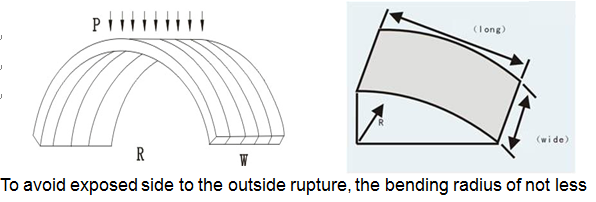

(D). To install curved PC sheet

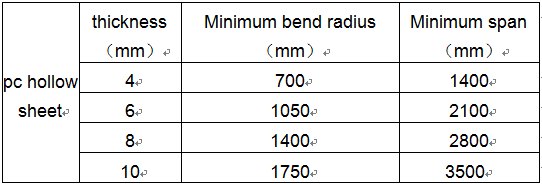

Yuemei PC sheet can be curved to install as per its curve structure, but PC sheet’s curving radius cannot be less than its minimum curving radius, so it will not influence sheet’s technique factor from the power caused by curving. PC sheet must follow the way of length to install rather than way of width to install.

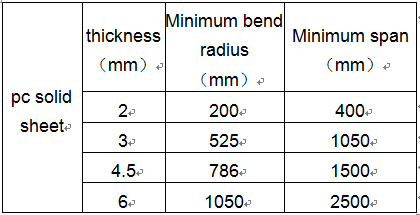

When cold bending, bending direction shall be perpendicular to the sheet tendons direction, the hollow sheet cold bending radius must be greater than 175 times of its thickness, polycarbonate solid sheet cold bending radius must be greater than 100 times of its thickness (for less than 3mm) 3mm or above polycarbonate solid sheet cold bending radius must be greater than 175 times of its thickness. Cold bending radius

formula

R =(1/2)h+m2/(8h)

R =bending radius

h =sagitta

m = span

1. PC hollow sheet

The most important feature of PC hollow sheet is it can be cold bended in different bending radius arch along the ridge rib, not only to improve the lighting area, satisfy the building arts design bending requirements. And improve the bearing capacity of the sheet, ordinary glass is unmatched. The correct bending direction of sheet as below.

15

PC Hollow sheet minimum curving radius

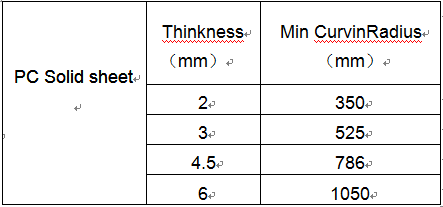

PC solid sheet has good toughness and cold-bending features, can be designed into various arched structure, its radius must be greater than the radius of curvature of the limits of the PC sheet. The following table shows some of the specifications of the PC solid sheet limit the radius of curvature.

PC Solid sheet minimum curving radius

3. YUEMEI PC sheet cleaning and maintenance

16

Follow the correct steps, use suitable cleaning solvent and tools regularly cleaning plates, make sheet beautiful and extend sheet life:

1. When cleaning, warm water must be under 60°C, washing with neutral detergent,cannot use the erosion effect detergent on the PC sheets, for example, alkaline substances or cleaning agents incompatible with polycarbonate sheet.

2. Soft cloth or sponge dipped in a neutral soap or detergent, gently clean the dust and dirt on the sheet, forbid using coarse fabric or brush touch sheet surface, never use scraper, razor or other sharp tools scraping the hollow sheet; avoid incompatible chemicals direct touch the PC sheet.

3. Must be use water rinse dirt thoroughly.

4. When the sheet surface have grease, wet paint, rubber track, can use moistened soft cloth with absolute alcohol to wipe off.

5. After cleaning, rinse with cold water and use soft cloth dry sheet to prevent leaving water.

Recommended anhydrous alcohol, neutral detergent, scrub with a sponge or soft

cloth sheet, then rinse.

Special Note:

Alkaline solution can not be used, it will erode the sheet surface. Forbid use esters,ketones, halogenated hydrocarbons, and anything can dissolve or swell polycarbonate.

4.Announcements

1. Construction announcements

(1 ).Select the appropriate thickness sheet and reserve the PC expansion coefficient.

(2).Cut with power tools (including the “carbonation” circular saw).

(3).Remove the protective film after installation (protective film can not be under sun and rain over two days).

(4).Avoid fixing screws on PC sheet, if cannot be avoided, the PC board hole should be larger and use a retainer screws, don’t fix too tight.

(5).When cleaning, use a mild soap or detergent, sponge or soft cloth to wipe, and then cleaning thoroughly with warm water.

(6).Do not fix with pull nails and self—tapping screws directly (easier for thermal expansion or rupture, cause damage).

(7).PC sheet have thermal expansion or contraction, to ensure that the surface is flat and beautiful after construction and PC sheet durability, it is recommended that construction to avoid interval use a PC sheet.

17

(1)In connection profiles or inlay slot effective space must be remained so as for the sheet expansion and movement when it get pressed. Linear coefficient of thermal expansion of pc hollow sheet is 7 x 1O-5m/mk, it means the temperature is increased by 1 °C, 1m x 1m sheet along the length direction of each expansion is 0.075mm. Four Seasons temperature differs according to the

location of the project, the user will be required to calculate the installed gap data: such as the northern region, the highest temperature is 40 °C, the lowest temperature is -30 °C, 1m x 1m sheet reserved installation space of 0.07 x 70=4.9mm.

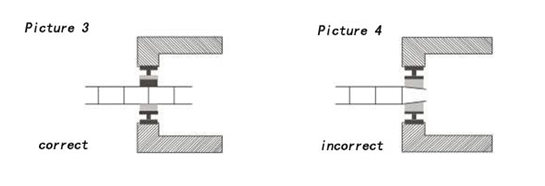

(2).sheet clamped part should contain in at least one rib, or the edge of the sheet is engaging at least 20mm, as shown above, in general, the profiles constituted the total depth of the slot should include the engagement of 20 mm thermal expansion and deformation required to set aside a gap.

5. Processing

Cutting tools: We recommend using the ordinary round (tungsten carbide), band saws, wire saw, bow hacksaw, and portable chainsaw saw

Drilling tools: We recommend using a hand drill or electric drill

(metal drill).

Sawing and drilling, sheet should be clamped on the workbench

to avoid tremor

At normal temperature, pc hollow sheet minimum bend radius is

175 times of sheet thickness.

18

Cold bending, bending direction perpendicular to the pc hollow sheet ridge ribs direction.

Use a clean dry compressed air to blow off the sawdust.

When sawing completed, seal edges with anti-dust tape, in order to avoid the intrusion of dust.

It is very easy to cut PC sheet accurately with standard tools in the workshop, these tools include circular saw, manual saw and steel saw. The sawdust in the sheet channel can be blowed by clear and compressed air. The circular saw should be equipped with fine serrated blade. When electrical saw or manual saw are used, it should be clamped on the table to avoid vibration. It should be no notch or saw dust after sawing. As to thin sheets, you can cut with sharp reamer directly.

Drill : You can drill holes by manual drill or power drill. There should be holder under the drill to avoid Sloshing during work.

19